Workflow Optimization

Performance solution by veterinary microbiology diagnostics experts

- Improved laboratory organization

- Streamlined workload

- Increased productivity

További tájékoztatást szeretne?

Faced with an increasingly challenging environment, it’s time to look at your lab from a different angle.

bioMérieux Industry, as a Microbiology expert, has adapted and applied LEAN techniques to meet each lab’s specific needs and challenges.

Workflow optimization through LEAN methodology

LEAN is a methodology developed by Toyota for manufacturing and involves a set of principles, practices and methods for designing and improving processes. The main objective of LEAN is to maintain the quality of production with less work and reducing time between the customer request and delivery of final results by reducing or eliminating “waste” (non-added value task).

bioMérieux : your transition partner

Based on the combination of our microbiology expertise and LEAN knowledge, we can help you identify opportunities to remove “waste” to optimize your organization and increase your efficiency.

As your partner, we analyze your laboratory to provide you tailor-made, high-performance solutions.

bioMérieux Workflow Optimization Solution will enable you to:

- Increase productivity

- Streamline processes

- Optimize cost

- Focus lab personnel on tasks with higher added-value

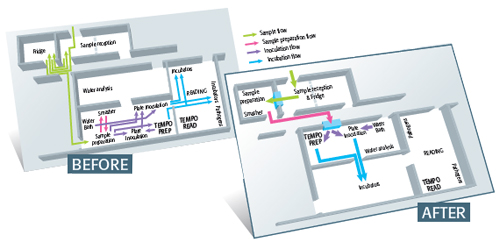

Graph: Spaghetti diagram of current workflow (BEFORE) and new implemented workflow (AFTER)

BEFORE : Flows crossing and lots of transports, movements

AFTER : Forward motion and reduced fatigue for the lab staff

bioMérieux Workflow Optimization Solution recommendations lead to new optimal lab layout with continuous flow, a more streamlined workload, and increased productivity: minimum 30% improvement gains.

4 STEPS TO ENHANCE LAB PRODUCTIVITY

Together we will analyze your lab structure and design a roadmap to optimize your laboratory workflow.

PRE ASSESSMENTEstablish your current situation and processes according to your lab’s specifications

Estimate potential and theoretical productivity gains

LAB PERFORMANCE ASSESSMENT

Evaluate workload, resources and space utilization in your laboratory

Analyze bottlenecks in your laboratory workflow

Propose recommendations, new layout and road map tailored to your lab

IMPLEMENTATION FOLLOW-UP

Implement layout effectiveness and work station design

Reach the productivity gains expected

KAIZEN EVENT

Enhance your lab performance by applying continuous improvement tools and involving your lab staff

Sustain and optimize your working conditions

lean-lab.png

Case study applied to microbiology :

“The Lean approach to optimize quality indicator testing in a microbiological laboratory” presented and accepted to IAFP European Symposium, Poland, 2012.

“Thanks to Workflow Optimization, our lab has gained efficiency (41%), flexibility, and it helps us to manage our daiIy variable workload.I would really recommend this process as it allows us to continuously improve our performance.”

Ana Martins, Lab Manager, ControlVetTM, Portugal